All Terrain Vehicle

Conquer Every Terrain

Project: All Terrain Vehicle

Project duration: 1 Year

Role: Team Captain & Design Lead

Worked on:

- Design & Manufacturing calculations

- Mechanical design & assembly of parts in all domains

- Ergonomics & Aesthetics

- CNC Manufacturing

- Testing

INTRODUCTION

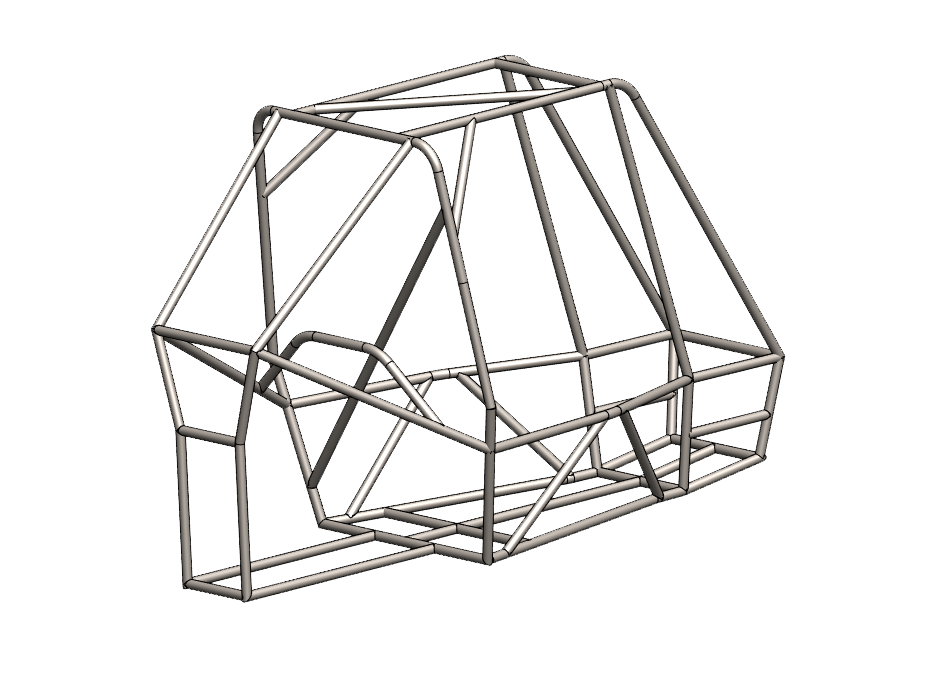

The All-Terrain Vehicle (ATV) project for BAJA 2019 is an exciting venture undertaken by our team of enthusiastic and skilled engineering students. The project aims to design, manufacture, and compete with a robust and high-performance ATV in the prestigious BAJA SAE (Society of Automotive Engineers) competition. Our vehicle was tailored to withstand challenging terrains, display exceptional off-road capabilities, and showcase innovative engineering solutions.

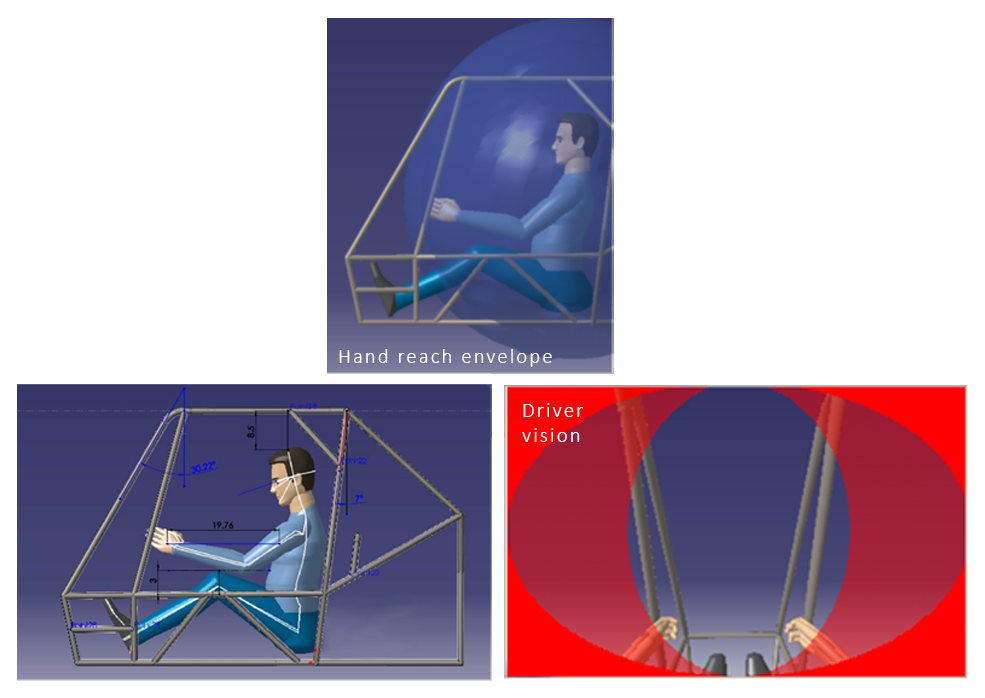

By leveraging a mannequin model within the CAD software, precise and accurate fine-tuning of driver ergonomics was achieved. Detailed simulations and iterative adjustments allowed for the perfect alignment of controls and seating. This human-centric approach resulted in an all-terrain vehicle that prioritized driver comfort, safety, and optimal performance.

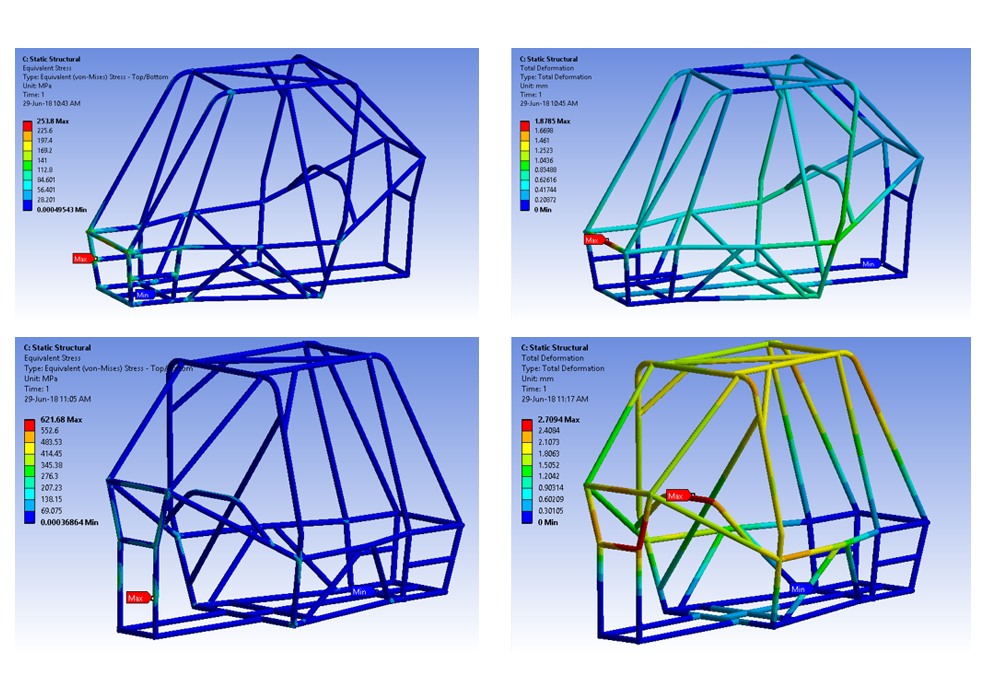

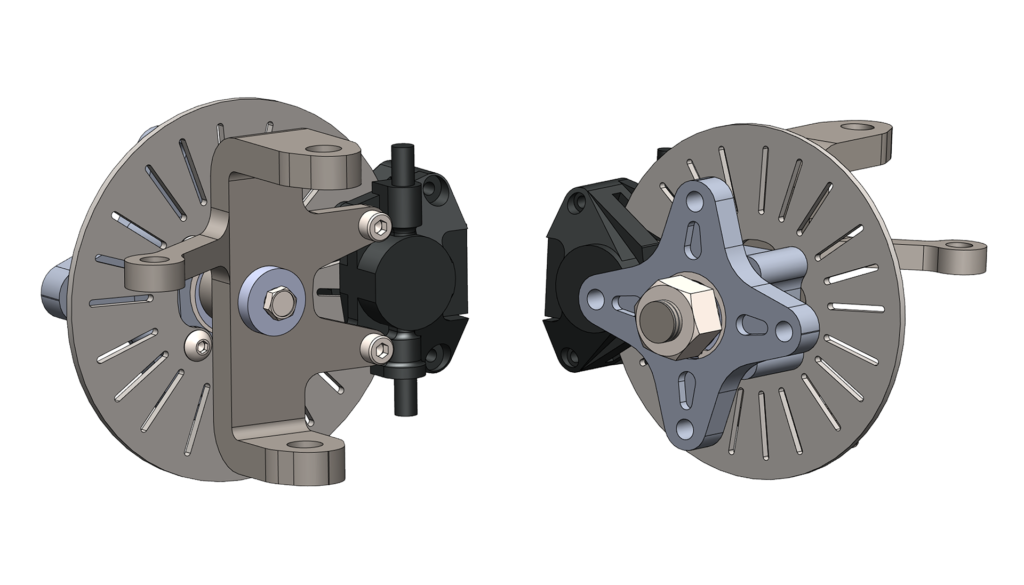

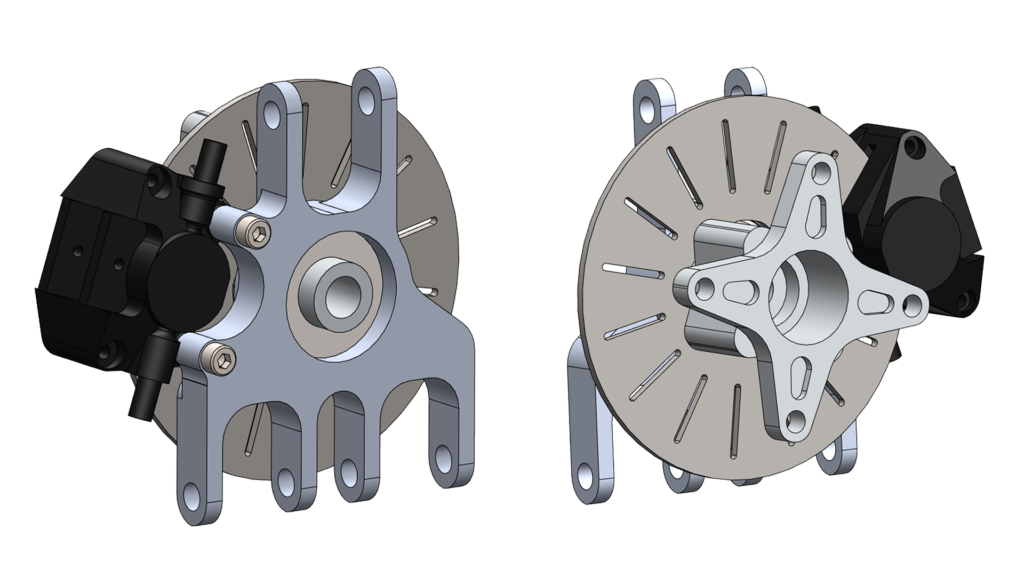

In the pursuit of creating a high-performance and robust wheel assembly, our team employed advanced structural analysis and topology optimization techniques. This innovative approach enabled us to refine the design of crucial components, including the hub, knuckle, and brake disc, resulting in an optimized wheel assembly that met stringent performance criteria while minimizing weight and material usage.

Utilizing structural analysis, we subjected the wheel assembly components to simulated loading scenarios, evaluating stress distribution and deformation under various operating conditions. This comprehensive evaluation allowed us to identify potential weak points and areas of stress concentration, guiding us towards targeted improvements.

Through the unwavering dedication of our incredible team, we achieved a significant milestone by winning the award for the Sled Pull Event at SAE BAJA 2019. The event truly put our ATV’s capabilities to the test, demanding immense pulling force, optimal weight distribution, and superior traction. Our victory stands as a testament to our team’s collaborative effort and relentless pursuit of perfection, enabling us to conquer the challenging course with determination and hard work.